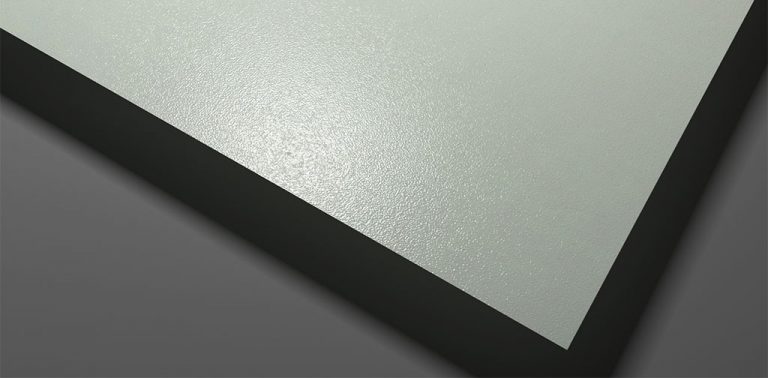

PTFE Coated Glass Cloth: PTFE coated glass cloth was created by DuPont in the 1960s and has been used to build tensile fabric structures since the early 1970s. PTFE/Glass’s high tensile strength coupled with high performance durable coating and non-combustible substrate make it the material of choice for permanent longspan architectural installations worldwide.

Comprising fiberglass (B yarn) woven fiber substrate covered with PTFE resins, this architectural material has high heat resistance (700-800 degrees Celcius) and is unaffected by UV light. Available in fully coated material for weatherproof roofing applications and also mesh (open weave) for interior sound absorption and facade applications to enhance thermal performance of buildings.

PTFE/Glass has approximately 1/30th the weight of a traditional steel roof, thereby decreasing construction costs of support structures and foundations. This also makes PTFE/Glass desirable from a sustainability perspective.

High reflectivity coupled with low absorption rate of sunlight as well as low heat capacity, means reduced solar energy influx into a building, resulting in energy savings.

The light transmission of PTFE/Glass ranges from 9-14% providing natural diffused light transmission to the internal environment under a PTFE/Glass roof/canopy. Dramatic night time lighting effects can be achieved with LED lighting onto PTFE/Glass roofing due to it’s light diffusing properties.

Due to the low friction coefficient of PTFE (Teflong) coating combined with its water repellancy, dust and dirt wash away with the action of rain. Minimal cleaning is required.

PTFE/Glass has been tested to AS1530.2 and 3 with extremely low flammability, spread of flame, ignitability, and smoke developed indices. The glass fiber substrate is non-combustible. This makes PTFE/Glass the material of choice for cladding in high risk fire zones.

PTFE coatings are unaffected by UV light and airborne pollutants and therefore maintains function and safety for minimum of 30 years.

Due to various factors, noted below, PTFE/Glass makes a significant contribution to green construction: